Effect of mean load, load range, and frequency on the power generated by piezoelectric crystals

S.M. Allameh, O. Akogwu, W.O. Soboyejo

Abstract

This paper presents the results of a preliminary study of the effect of loading parameters on the performance of piezo crystals. The output power of the crystals was observed to increase with parameters such as frequency and the dynamic load range but slightly decreased with mean load. The efficiency of the crystal was calculated based on the mechanical energy applied to the piezo crystal. The ratio of the electrical output to mechanical energy input was taken ad the efficiency of the crystal. This ratio was seen to increase with the cycling frequency and with the dynamic load range. However, increasing mean load caused the efficiency to drop significantly. The implications of this study in the design and applications of piezoelectric power generators are discussed.

I. Introduction

Conversion of kinetic energy

to electrical energy has been investigated by a number of researchers for

electrical power generation [1-6].Piezoelectric materials have

been investigated as essential elements for high-power pulse generation [1-6]. Electrical energy is

generated when an applied force overcomes internal inductance or capacitance of

a material. For a piezoelectric material this internal fields are stored the

ohmic lattice of the material. Mechanical deformation of this material by

applying load in static or dynamic cases generates the output voltage required

to power the piezoelectric pulse generator. Experiments have been performed by

applying quasi-static or dynamic stress [7]. They reported that dynamic

and quasi-static loading produced equal magnitudes of output voltage. They also

reported that the dynamic loading produced a unidirectional voltage while the

quasi-static case generated a bi-directional voltage. However, Engel at al [5] have reported different

results for similar experiments performed on the piezoelectric material for

both stresses. They discovered that the dynamic loading yielded a much higher

output voltage (up to 10 times more) than the quasi-static case. They compared

their experimental measurements on power generation with predictions of simulations. The theory finds that the material thickness to

cross sectional area ratio (TAR=hpiezo /A) can be used to maximize

output power. A higher TAR results in a higher output voltage but a lower

output current. In an effort to maximize output power, the voltage and current

have to be maximized. The overall effect of thickness to area ration (TAR) will

be dominated by the larger contribution of voltage to the product of voltage

and current. In other words, piezoelectric power output increases with

increasing TAR.

To achieve this, two models have

been proposed. The mechanical model that provides information on the

displacement (deformation) of the material due to applied force and thus the

generated voltage. The electrical model is used to find circuitous conditions

needed to generate maximum current.

The purpose of this study is to investigate and present the output power generated by the piezoelectric power generator based on the proposed models. In this effort, we set up experiments comparable to earlier works and dynamically loaded the system at different frequencies, load ranges and applied different loads (resistor values) at the output. The results obtained are also discussed.

II.

Experimental Procedure

Piezoelectric crystals were

obtained from Staveley Sensors Inc., East Hartford, CT. Various characteristics

of the crystal is tabulated in Table. They had a diameter of 25 and a thickness

of 6.3 mm. The crystals were sandwiched between two Al blocks to acquire or

impart electric signal to them. One Al block were then placed in load train

insulated from other components by a ZrO2 block. The ZrO2,

was housed in an Al block connected to load cell which was mounted on an x-y

stage. The other Al block covering the piezo crystal was connected to a

piezoelectric actuator made by Polytec PI, Inc. (MA, USA). The latter was

powered by a wave function generator that produced sinusoidal signals, with

different frequencies, different amplitudes, and different offsets. The signal

from the wave function generator was then sent to a PI amplifier and then fed

to the PI piezoelectric actuator.

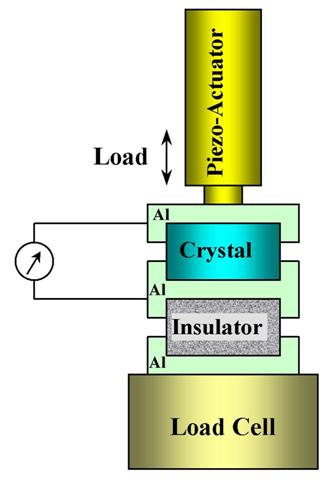

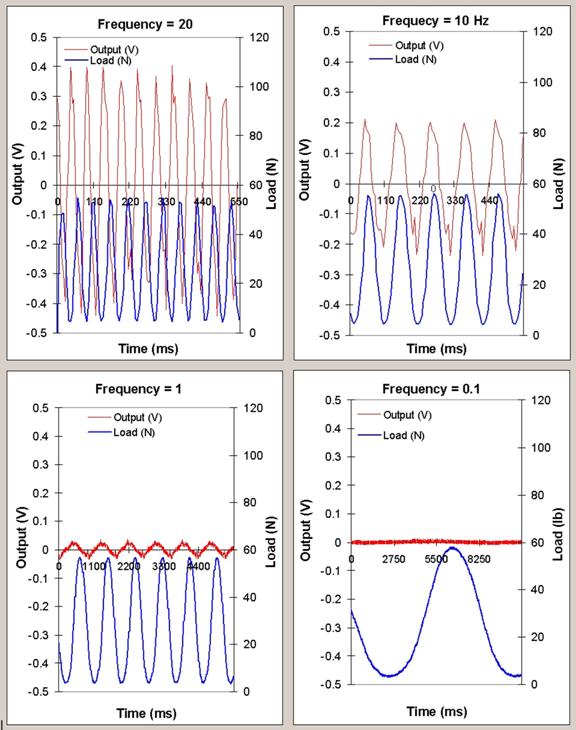

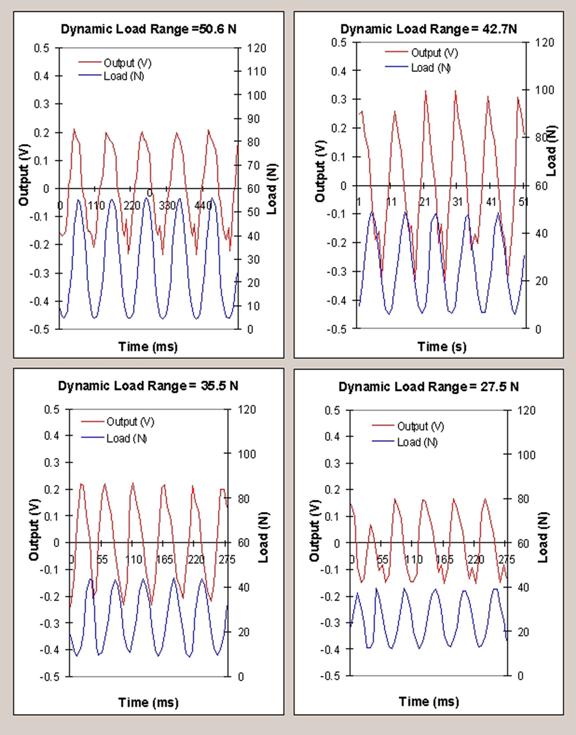

A range of frequencies from 0.1 to 20 Hz were chosen for the first set of tests conducted at a cyclic load amplitude of 52 N and a constant mean load of 30 N. One set of experiments was conducted with a varying load range of 27 to 54 N at a constant mean load 36 N. Another set of tests was performed at a constant load range of 53 N but at a varying mean load of 3.7 N to 4.4 N. The set up is shown in (Figure 1).

III. Results and Discussion

(a) Effect of Loading

The results of mechanical testing

of the piezo crystal are summarized in (Figure 2)(Figure

3)(Figure 4).

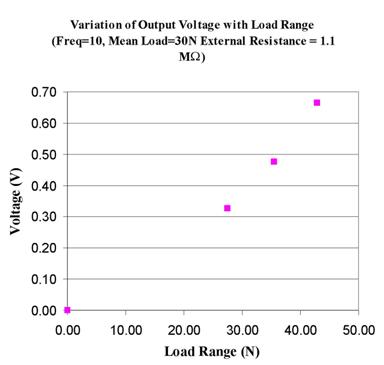

The variation of the output voltage with load is shown in (Figure 5). The output voltage increases with

the load range in a near-linear manner.

It clearly shows that the dynamic range of the applied load is directly

responsible for the output power.

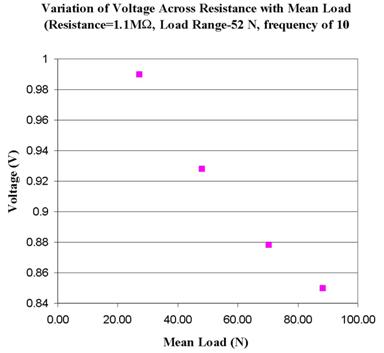

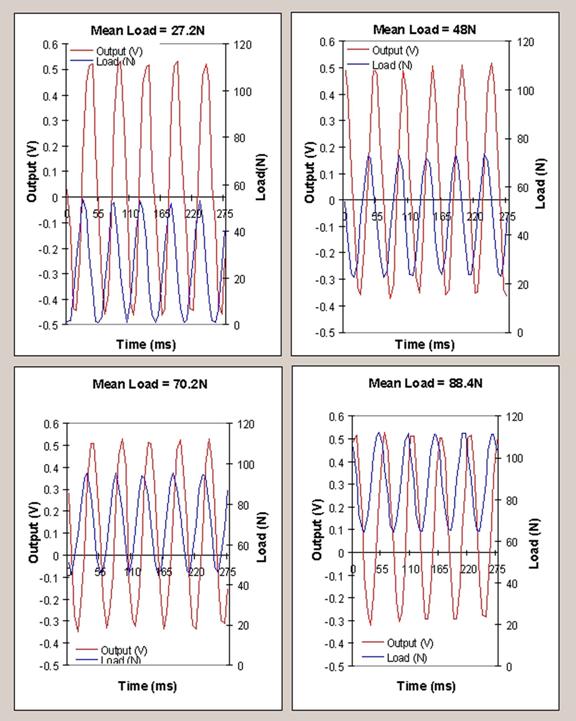

The effect of mean load is

illustrated in detail in (Figure

6). The tests were performed at a

constant load range to exclude its effect on the output voltage. The frequency

was also maintained at 10 Hz. The effect of mean load on the output voltage is

seen to be small. The results show an inverse dependence of the output voltage

on the mean load. This implies that for a given dynamic load range, the highest

output power is achieved at lowest possible mean load. Mean load here may be

thought as isostatic pressure in piezo crystal that affects the mobility of

electrons in the crystal lattice.

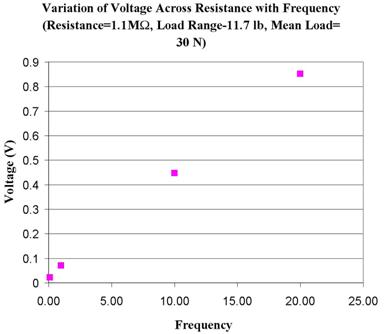

The effect of frequency on the

output voltage is shown in (Figure

7). The change in frequency is

seen to change the out put voltage significantly. However, this change in

output voltage on the loading frequency is linear as seen in (Figure 3). The linear dependence of the output

voltage on frequency can be understood given the fact that more mechanical work

is performed when the piezo crystal is loaded at a higher frequency. In fact

the mechanical work that is performed on the piezo crystal is proportional to

the area under the load-displacement curve. However, this area does not

significantly change with the strain rate for this crystal, (e.g. same amount

of work is performed at a higher strain rate), then more cycles will mean more

energy input into the crystal. This higher energy input is seen to have yielded

a higher energy output (manifested by a higher output voltage). Doubling the

frequency to 20 Hz translates into a near-doubling in the output voltage as

seen in (Figure

3).

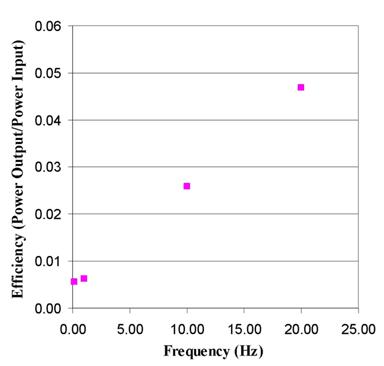

All these tests were performed with

a resistor attached to the crystal. This resistor was chosen to be 1.1 MW. In this manner, the output voltage was representative of the

power output of the crystal through the relationship: P=V2/R. The

dependence of the power output on frequency and dynamic load will then be

through this power law, meaning, doubling the frequency will quadruple the

output power. An interesting outcome of this experiment is that the power

output increases with square of the values for frequency and dynamic load

range. This means that the efficiency of the crystal is a function of the

frequency and load range, increasing with both of these factors.

Two important conclusions can be

made based on the outcome of these experiments. The first one points to the

application of piezoelectric crystals in higher frequency applications where

higher efficiencies are achieved. The second one points to the higher dynamic

load range applications where efficiency maximizes. In both of these

applications the mean load should be minimized in order for the efficiency to

be optimum.

The effect of dynamic load range is

shown in (Figure

8). Increasing the dynamic load

range at constant mean load at a frequency of 10 Hz is seen to increase the

output voltage of the piezo crystal. The increase in the output voltage with

the load range is summarized in (Figure

8). There is a significant change

in the output voltage with an increase in the dynamic load range. The effect is

seen to be much greater at higher load ranges. The magnified effect of load

range will greatly boost the efficiency at higher load ranges.

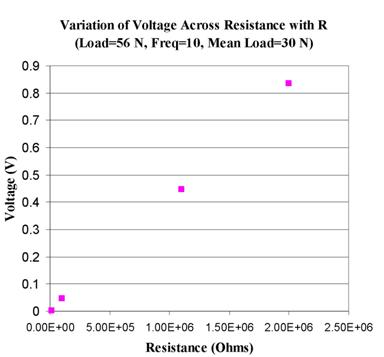

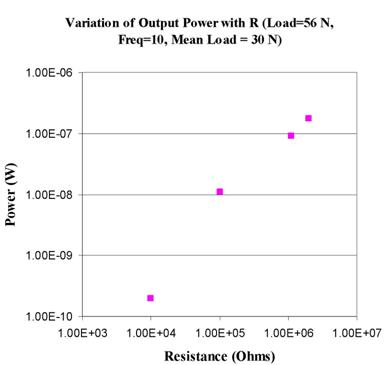

The output voltage of the crystal

varied linearly with the value of the resistor used across the two leads of the

multimeter. This variation is depicted in (Figure

4). The output voltage increases

linearly with the resistance attached to the crystal. Since power is a square

function of voltage, and increase in the resistance will greatly increase the

power extracted from the piezo crystal.

The effect of cyclic loading on the

output voltage can be compared to the results of Engel et al.[1]. The output voltage

predicted from the formula

![]() (1)

(1)

where Vpiezo is the voltage

across the piezo crystal, d33 is the force sensitivity of the crystal, Cpiezo

is the capacitance of the crystal F is the applied force. Equation (1) predicts

a voltage of about 10 V at a load level of 50 N. Without the external resistor,

the cyclic voltage, measured in this study was bi-directional with a total

range (minimum to maximum) of ~ 5 V.

The power output of the piezo

crystal as determined by the voltage across a resistor placed parallel to the

piezo varies with the resistor. This variation in illustrated in (Figure 9). This log-log plot clearly shows an

increase in the consumable power extracted from the piezo crystal with the

value of the external resistance. It should be noted that power consumed in the

external resistance is inversely proportional to the value resistance.

![]() (2)

(2)

However, the output voltage

increases with increasing resistance. Since the effect of voltage on the power

is greater than the effect of resistance, the net effect of increasing

resistance on the amount of extracted power is positive.

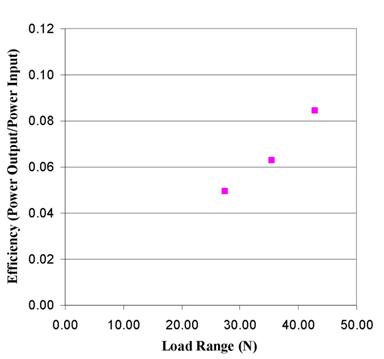

(b) Efficiency of Piezo Crystal

For

piezo electric crystal with a capacitor of 2.8 nF under cyclic loading, the

stored energy per cycle time tcycle can be calculated as:

(3)

(3)

With no external resistance, the

output power of the piezo will be ~ 3.75 x 10-7 W. As expected, this

value is greater than the energy consumed by the external 2 MW resistance (e.g. 1.75 x 10-7 W). To calculate the

efficiency of the crystal, under different loading conditions, we need to

determine the amount of mechanical work performed on the crystal.

(4)

(4)

Here force (F), applied on the crystal, is measured directly by the load cell in the load train. It will include forces originating from the acceleration of the piezo mass, damping of the piezo crystal and the elastic response of the crystal. Since the sum of all forces is measured instantaneously, there is no need to calculate various force components separately. Using parameters presented in Table 1 for the piezo crystal used in this study, the efficiency is determined as the ratio of the electrical power output of the crystal to the mechanical power provided to the crystal to the consumed output using Equation (4).

The results of variation of the

efficiency with the dynamic load range is presented in (Figure 10).

As expected the efficiency of the piezo crystal increases with increasing load

range. For all data points, the mean load has been maintained constant at 30 N.

The increase in the efficiency is nearly linear. A similar trend is observed in

the variation of efficiency with frequency (Figure

11). More mechanical work applied

on the crystal generates more electrical power. Frequencies used in this study

are small enough to allow full relaxation of the crystal between loadings. This

leads to additive effect of sequential cycles that impose mechanical work on

the crystal.

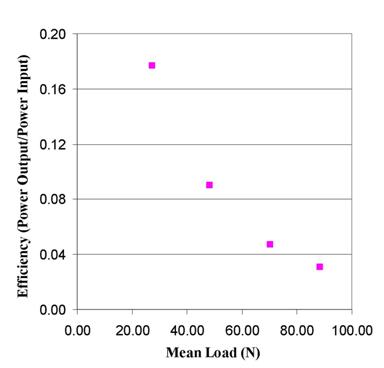

The most intriguing result of this

study is illustrated in (Figure

12). The efficiency of the piezo

crystal drastically decreases with increasing mean load. There are two

contributions to this effect. The smaller contribution comes from the

hydrostatic pressure that is applied to the crystal at higher mean loads. This

reduces the output voltage, possibly by affecting the mobility of the electrons

in the crystal lattice of the piezo material. The more important factor in the

loss of efficiency with the mean load comes from the huge increase in the

mechanical work expended in the actuation of the piezo crystal. Higher mean

load dramatically increases the mechanical work. In conjunction with a constant

load range, it leads to a significant drop in efficiency.

(c) Implications

The results of this study shed

light on a number of important parameters that affect the efficiency of piezo

electric crystals. With the current renewed interest in alternative sources of

energy (as a result of higher oil and gas prices), optimization of processes

that produce electric energy from natural forces such as wind and waves becomes

important.

Some factors such as higher TAR

(thickness to area) ratio that are known to increase the power output of the

piezo crystals. Our results show the effects of some other factors such as the

effect of mean load that reduces the efficiency of power generation through the

use of piezo crystals. This implies that for better efficiency, the dynamic

load range should be chosen in a manner that minimizes the mean load.

The power extraction from the piezo

is also shown to depend on the external resistance used to measure it. At a

higher electrical resistance, power extraction is higher. This means lower

loads on piezo electric generators will yield higher efficiencies.

IV. Summary and Conclusions

Based on the results obtained in cyclic loading experiments performed on a piezo crystal the following conclusions can be made:

(1)

The output voltage of a piezo crystal across a

resistor is an indicator of the power output of the crystal. The magnitude of

this output voltage increases with dynamic load range, frequency and decreases

with increasing mean load

(2)

The power output of the crystal, as expressed by V2/R

greatly increases with the dynamic load range and with frequency.

(3)

The efficiency of a piezo crystal, as a function of

the power consumption through a resistor depends on frequency and load range.

It has been demonstrated that efficiency increases with frequency and with

dynamic load range. The efficiency of the piezo drastically decreases with

increasing mean load

(4)

The optimum power generation is shown to commence with

highest frequency, highest dynamic load range and lowest mean load.

References

1. T.G. Engel, C. Keawboonchuay, and W.C. Nunnally,

"Energy conversion and high power pulse production using miniature

piezoelectric compressors," IEEE

Transactions on Plasma Science, 2000, 28

(5) pp. 1338-1341.

2. T.G. Engel, W.C. Nunnally, J. Becker, R. Rahman, and C.

Keawboonchuay, "Research progress on compact kinetic-to-electrical energy

converters," Presented in Proceedings

of the 12th International Pulsed Power Conference, 1999, Monterey, CA, USA,

C.K. Stallings, H., Editor, IEEE, pp. 1287-1290 vol.1282.

3. T.G. Engel, W.C. Nunnally, and N.B. VanKirk, "Compact

kinetic-to-electrical energy conversion," Presented in Digest of Technical Papers 11th IEEE

International Pulsed Power Conference, 1997, Baltimore, MA, USA, G.V. Cooperstein,

I., Editor, IEEE, pp. 1503-1507 vol.1502.

4. C. Keawboonchuay and T.G. Engel, "Maximum power

generation in a piezoelectric pulse generator," IEEE Transactions on Plasma Science, 2003, 31 (1) pp. 123-128.

5. C. Keawboonchuay and T.G. Engel, "Electrical power

generation characteristics of piezoelectric generator under quasi-static and

dynamic stress conditions," IEEE

Transactions on Ultrasonics, Ferroelectrics and Frequency Control, 2003, 50 (10) pp. 1377-1382.

6. C. Keawboonchuay and T.G. Engel, "Design, modeling, and

implementation of a 30-kW piezoelectric pulse generator," IEEE Transactions on Plasma Science,

2002, 30 (2) pp. 679-686.

7. C.-N. Xu, M. Akiyama, K. Nonaka, and T. Watanabe,

"Electrical power generation characteristics of PZT piezoelectric

ceramics," IEEE Transactions on

Ultrasonics, Ferroelectrics and Frequency Control, 1998, 45 (4) pp. 1065-1070.

Table I. Characteristics of

the piezo electric crystal used in this study

Properties |

Symbol |

Magnitude |

Units |

|

Diameter |

d |

15 |

mm |

|

Thickness (mm) |

h |

3 |

mm |

|

Young’s Modulus |

E |

111 |

GPa |

|

Capacitance |

Cp |

2.08 |

nF |

|

Load proportionality constant |

d33 |

598 |

C/N |

List of Figures

Figure 1. Schematic of experimental setup for the examination of effect of load range, mean load and frequency on power generation of piezo crystal

Figure 2. Effect of mean load on output voltage

Figure 3. Effect of frequency on output voltage

Figure 4. Voltage vs resistance

Figure 5. Voltage vs Load Range

Figure 6. Variation of piezo crystal response with Mean Load

Figure 7. Variation of piezo crystal response with Frequency

Figure 8. Variation of piezo crystal response with dynamic load range

Figure 9. Variation of output power with resistance

Figure 10. Variation of efficiency with load range

Figure 11. Variation of efficiency with Frequency

Figure 12. Variation of efficiency with mean load